Dukunde Kawa

Acidity: Winey

Producer: 459 farmers organized around Mbilima Coffee Washing Station | Dukunde Kawa Cooperative

Variety: Bourbon

Growing Elevation: 1800-2100 Meters

Processing: Washed. Dried on Raised Beds.

Certifications: Certified Organic, Fair Trade. A female forward JBC coffee.

Region: Akanduga Village. Gakenke District. Rwanda.

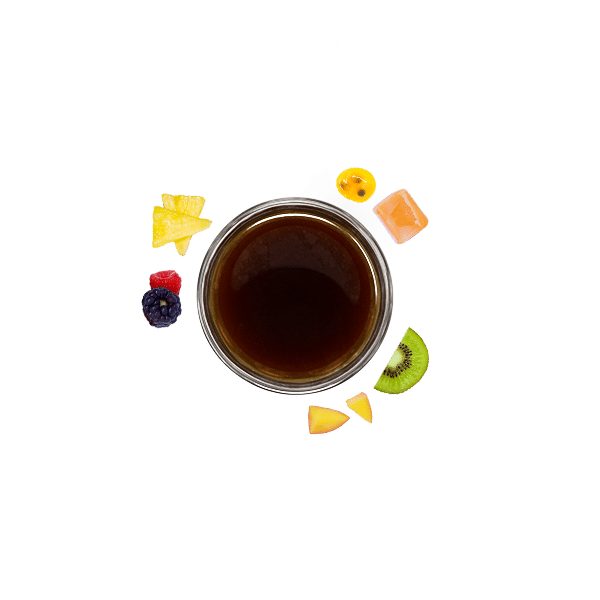

Dukunde Kawa is a producer group of over 2,000 farmer members that is well-known for its exceptionally bright and memorable coffees, as well as its commitment to sustainability and transparency. The cooperative carries many certifications including Fair Trade, Organic, Rainforest Alliance, and UTZ. Over 80% of Dukunde Kawa’s workforce is female. Since first organizing in 2000, Dukunde Kawa has received a number of sustainability awards from the SCA as well as placing in top spots at Rwanda’s Cup of Excellence. This particular lot from Dukunde Kawa was standout to our cuppers with tasting notes of tropical fruit, mixed berry, caramel, and orange zest.

This lot comes from Dukunde Kawa’s largest washing station Ruli which was established in 2005 and is the highest elevation that Dukunde serves (with farms sometimes surpassing even 2100 meters.) Processing at Ruli includes cherry sorting by the farmers themselves upon delivery. The cherry is then floated in a large receiving bay to identify and remove floaters (low-density cherry which is processed separately). Cherry is then depulped and the fresh parchment is graded immediately by flotation in a short channel. Fermentation usually lasts 18 hours and is completed without water. Once the dry fermentation is complete the parchment is soaked in fresh water between 18-24 hours to halt fermentation and the stabilize moisture content of the batch. After the soak the parchment is washed once again, this time in grading channels—long shallow concrete channels with water flowing through—which allows the parchment to naturally separate by density. From here, each separate density grade is moved to pre-drying tables to be hand-sorted for imperfections and gently dried to the touch. After the hand-sort is complete, the parchment is then moved to fully-exposed drying tables to finish drying, a process that takes between 14-21 days depending on the climate.